Characterization of Hydroxyapatite From Kupang Shells and Its Synthesis with Polycaprolactone for 3D Printing Filament

Main Article Content

Abstract

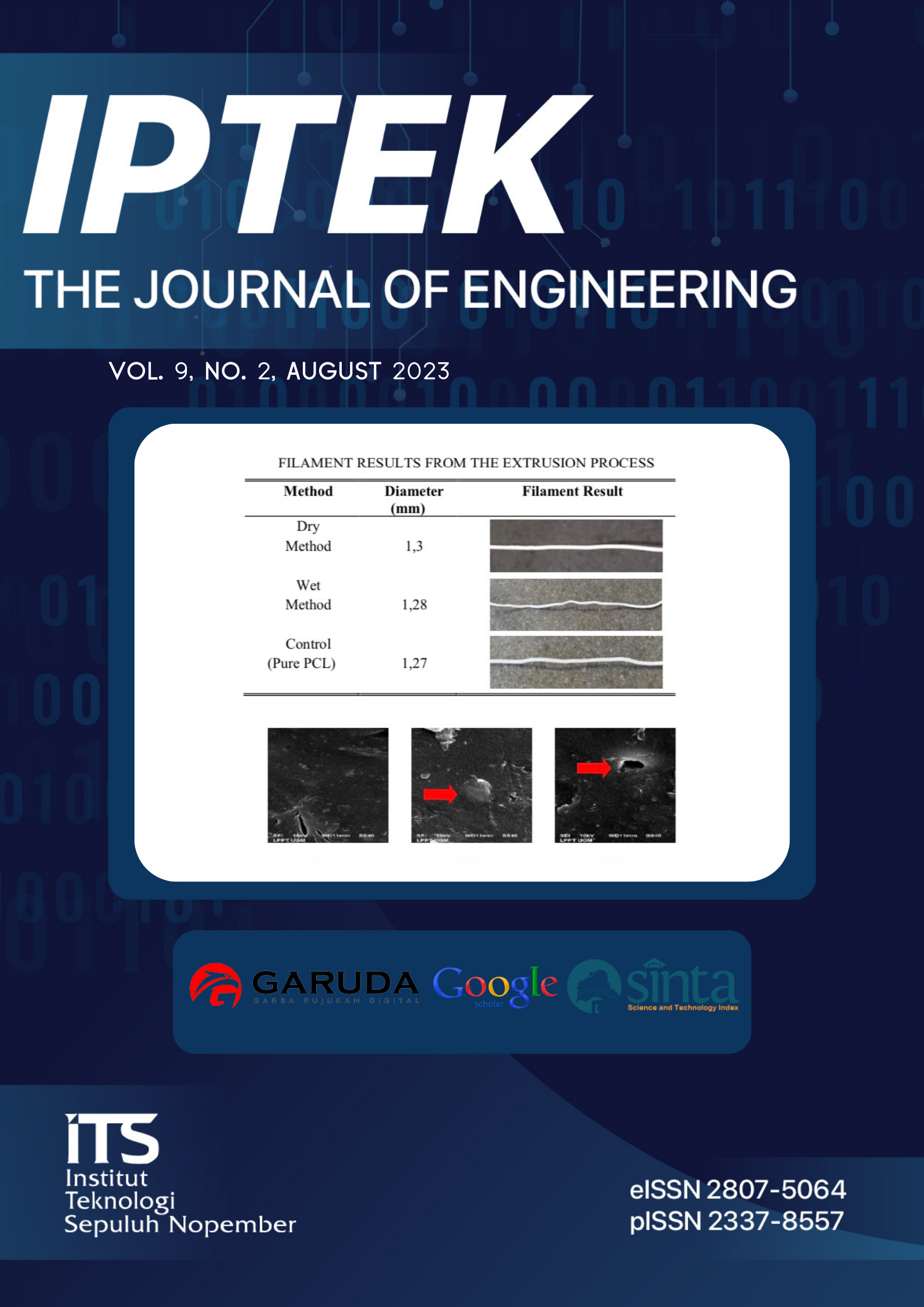

The number of deaths or fatalities due to accidents in Indonesia is increasing. In addition, traffic accidents can cause serious injuries such as damage to the skull. The bone implantation technique currently used is an autograft, but this technique has some limitations. This limitation of autograft can be overwhelmed with synthetic bone implants, one of which uses a mixture of Polycaprolactone (PCL) and Hydroxyapatite (HAp). A combination of HAp and PCL is recommended because the two materials complement each other's weaknesses and can increase elasticity and quality to produce suitable filaments for 3D printing processes. This study used hydroxyapatite from Kupang Shells by calcination and precipitation methods. Then do the test XRF, XRD, FTIR, and SEM to determine the quality. The results showed that HAp synthesized from Kupang Shells had potential characteristics as bone implants. Next, two methods were used to mix PCL with HAp as a 3D printing filament for bone implants: the dry and wet methods. After that, it is analyzed with SEM and Mechanical Strength. The results of the SEM test of HAp particles in the wet method have more even distribution and a smoother surface than in the dry method. The impact is visible on the filament's mechanical test, which shows better results in the wet method.

Article Details

How to Cite

Putra, A. F. P. ., Ningrum, E. O. ., Adiguna, E. ., Garin, M. ., Hanif, R. R. ., & Surono, A. . (2025). Characterization of Hydroxyapatite From Kupang Shells and Its Synthesis with Polycaprolactone for 3D Printing Filament. IPTEK The Journal of Engineering, 9(2), 47–51. Retrieved from https://journal.its.ac.id/index.php/joe/article/view/8179

Issue

Section

Articles