The Potential of Halal Anti-Foam Production from Vegetable Oil Derivatives: a Review

Main Article Content

Abstract

The foam that occurs in the process can cause problems with the effectiveness of the process or the quality of the final product. The economic consequences of uncontrolled foaming can be very significant and cause serious losses and require expensive operating changes. Foaming problems can be just as expensive as treating other types of problems, such as corrosion, fouling, or emulsion. Indonesia is known as the largest producer of palm oil, so it has the potential as a producer of downstream palm oil derivative products, especially halal anti-foam with renewable raw materials. In the food industry, only calcium alginate, monoglycerides (MGS), and diglycerides (DGS) are permitted. The use of renewable raw materials in industrial processes is one of the steps to realizing the Sustainable Development Goals, especially the second goal, which is zero hunger in 2030. The details of the mechanism of action and the use of anti-foam in the food, medicine, cosmetics, textile, oil refining, petrochemical, paint, and pulp paper industries were discussed. Furthermore, the potential use of palm oil as raw material for halal anti-foaming is very prospective, considering that there are not many palm oil-based anti-foam products applied in various food industries.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright

Authors who publish their manuscripts in this journal agree to the following terms:

- The copyright of each article remains with the authors.

- Halal Research Journal holds the right to publish the article first under the Creative Commons Attribution 4.0 International License.

- Authors may distribute their published manuscripts non-exclusively (e.g., to institutional repositories or as part of book publications), provided they acknowledge that the article was first published in this journal.

License

Articles published in this journal are licensed under the Creative Commons Attribution 4.0 International License. This license permits anyone to:

- Copy, distribute, adapt, modify, and create derivative works from the material in any form, including for commercial purposes.

- The condition is that proper credit must be given to the authors for the original work.

References

SI Karakashev and MV Grozdanova, “Foams and antifoams,” Adv. Colloid Interface Science. , vol. 176–177, pp. 1–17, 2012, doi:10.1016/j.cis.2012.04.001.

ND Denkov and KG Marinova, “Antifoam effects of solid particles, oil drops and oil–solid compounds in aqueous foams,” Colloid. Parts. Liq. Interfaces , vol. 9780521848, pp. 383–444, 2006, doi:10.1017/CBO9780511536670.011.

BPOM, "Regulation of the Food and Drug Supervisory Agency on Food Additives," Food and Drug Supervisory Agency of the Republic of Indonesia. , pp. 1–10, 2019.

R. Febryantara, E. Hambali, H. Fujita, and A. Suryani, “Study on palm oil-based glycerol ester as an antifoaming agent,” IOP Conf. Ser. Earth Environment. science. , vol. 209, no. 1, 2018, doi:10.1088/1755-1315/209/1/012038.

AML Odaneth AA, Kavadia MR, Yadav MG, “Production of glyceryl monostearate by immobilized candida antarctica B lipase in organic media,” J. Appl. Biotechnol. bioeng. , vol. 2, no. 3, pp. 96–102, 2017, doi: 10.15406/jabb.2017.02.00031.

CC Yu, Y. Lee, BS Cheon, and SH Lee, “Synthesis of Glycerol Monostearate with High Purity Synthesis of Glycerol Monostearate with High Purity,” Bull. Korean Chem.Soc , vol. 24, no. December, pp. 1229–1231, 2014, doi:10.5012/bkcs.2003.24.8.1229.

Zakwan, E. Julianti, and Z. Lubis, “Production mono-diglyceride (MDG) from refined deodorized palm oil (RBDPO) by enzymatic process,” Int. Food Res. J. , vol. 24, no. 1, pp. 56–59, 2017.

BTB Hue et al. , “Monoglyceride and monoglyceride derivatives from glycerol generated in catfish based biodiesel production process Monoglyceride and monoglyceride derivatives from glycerol generated in catfish based biodiesel production process,” pp. 4–11, 2019, doi:10.1088/1757-899X/620/1/012012.

PS Kong, Y. Pérès, WMA Wan Daud, P. Cognet, and MK Aroua, “Esterification of glycerol with oleic acid over hydrophobic zirconia-silica acid catalyst and commercial acid catalyst: Optimization and influence of catalyst acidity,” Front . Chem. , vol. 7, no. APR, pp. 1–11, 2019, doi:10.3389/fchem.2019.00205.

PRGarret, “The Mode of Action of Antifoams,” in Defoamng: Theory and Industrial Applications , PRGarret, Ed. Boca raton: CRC Press, 1992, pp. 1–118.

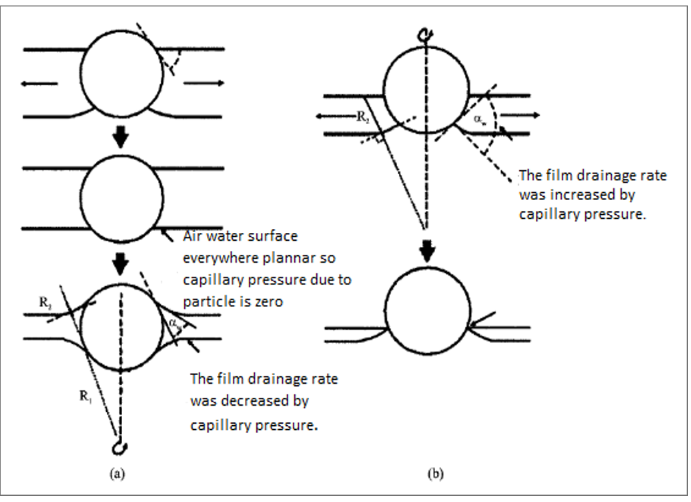

F. Abdolahi, MA Moosavian, and A. Vatani, “The Mechanism of Action of Antifoams,” J. Appl. science. , vol. 5, no. 6, pp. 1122–1129, 2005, doi:10.3923/jas.2005.1122.1129.

ND Denkov, “Mechanisms of foam destruction by oil-based antifoams,” Langmuir , vol. 20, no. 22, pp. 9463–9505, 2004, doi:10.1021/la049676o.

H. Daemi and M. Barikani, “Synthesis and characterization of calcium alginate nanoparticles, sodium homopolymannuronate salt and its calcium nanoparticles,” Sci. Iran. , vol. 19, no. 6, pp. 2023–2028, 2012, doi:10.1016/j.scient.2012.10.005.

B. Larsen, DMSA Salem, MAE Sallam, MM Mishrikey, and AI Beltagy, “Characterization of the alginates from algae harvested at the Egyptian Red Sea coast,” Carbohydr. res. , vol. 338, no. 22, pp. 2325–2336, 2003, doi:10.1016/S0008-6215(03)00378-1.

M. Fertah, Isolation and Characterization of Alginate from Seaweed , no. 2012. Elsevier Inc., 2017.

NR Rarokar, S. Menghani, D. Kerzare, and PB Khedekar, “Progress in Synthesis of Monoglycerides for Use in Food and Pharmaceuticals,” J. Exp. Food Chem. , vol. 03, no. 03, pp. 13–19, 2017, doi: 10.4172/2472-0542.1000128.

R. Berger, “Application of Antifoams in Pharmaceuticals,” in Defoaming: Theory and Industrial Applications , PRGarret, Ed. Boca Raton: CRC Press, 1992, pp. 177–189.

SJ Routledge, “Beyond de-foaming : productivity the effects of antifoams on bioprocess Abstract : Antifoams are often added to bioprocesses with little knowledge of their impact on the cells or product . However, it is known that certain antifoams can affect the growth,” Comput. Struct. Biotechnol. , vol. 3, no. 4, pp. 1–7, 2012, doi:10.5936/csbj.201210014.

VE Lewis and WF Minyard, “Antifoaming and Defoaming in Refineries,” in Foam: Fundamentals and Applications in the Petroleum Industry , LL Schramm, Ed. Washington, DC: American Chemical Society, 1994, pp. 461–483.

MRPorter, “Antifoams for Paints,” in Defoaming: Theory and Industrial Applications , PRGarret, Ed. Boca Raton: CRC Press, 1992, pp. 170–295.

R. Schumahcher, GD Voss, K. Oppenlaender, B. Wegner, and A. Hohmann, “Antifoams Based on Oil in Water Emulsions for the Paper Industries,” US 5,700,351, 1997.

R. Mardaweni, D. Setyaningsih, and MS Rusli, “Purification of Mono-Diacylglycerol from Palm Fatty Acid Distillate and Glycerol Esterification Using Solvent-Saponification Extraction and Molecular Distillation,” J. Teknol. eng. Pertan. , vol. 27, no. 2, pp. 192–199, 2017, doi:10.24961/j.tek.ind.pert.2017.27.2.192.

Directorate General of Plantations, “Statistics of national flagship plantations,” Sekr. Director General of Perkeb. Ministry. Pertan. , p. 1056 pp, 2021.

S. Rahkmawan, A. Suryono, F. Nofrida, and Suheri, Indonesia Foreign Trade Export Statistics 2020, Volume I . BPS RI/BPS-Statistics Indonesia, 2021.

D. Khatiwada, C. Palmén, and S. Silveira, “Evaluating the palm oil demand in Indonesia: production trends, yields, and emerging issues,” Biofuels , vol. 12, no. 2, pp. 135–147, 2021, doi:10.1080/17597269.2018.1461520.

N. Binhayeeding, S. Klomklao, and K. Sangkharak, “Utilization of Waste Glycerol from Biodiesel Process as a Substrate for Mono-, Di-, and Triacylglycerol Production,” Energy Procedia , vol. 138, pp. 895–900, 2017, doi:10.1016/j.egypro.2017.10.130.

C. Nazato, ADC Romero, and AL Abdalla, “Food Science and Technology | Note chromatography," no. 11052, pp. 527–531, 2019.

Y. Xiao, G. Xiao, and A. Varma, “A universal procedure for crude glycerol purification from different feedstocks in biodiesel production: Experimental and simulation study,” Ind. eng. Chem. res. , vol. 52, no. 39, pp. 14291–14296, 2013, doi:10.1021/ie402003u.